Additive Manufacturing - Machines and Processes

Additive Manufacturing - Machines and Processes

Additive manufacturing is an innovative manufacturing process in which 3D objects are built

The process begins with creating a digital 3D model of the desired object. This can be created using CAD data. Software divides the 3D model into a series of thin horizontal layers. The material used for printing, often metals in industry, is prepared as powder for the 3D printer. The 3D printer builds the object layer by layer. After each layer is completed, the material is cured or cooled according to its specific properties. The steps are repeated until the object is fully constructed.

Advantages of additive manufacturing

Advantages of additive manufacturing

| Design freedom for complex structures | |

| Efficient consumption of material | |

| Individualized productions from 1 piece | |

| Variety of materials expands application options |

| Weight reduction thanks to hollow components | |

| On-site production reduces transportation costs | |

| Cheaper than other manufacturing methods | |

| Faster production of innovative prototypes, components and tools |

Unsere Maschinen für die additive Fertigung

Weighing Systems and Equipment for Metal Powder Production in Additive Manufacturing

Additive manufacturing (AM) is the process of making objects by adding different materials: these process of using materials to make objects from 3D model data (source: Additive Manufacturing, 2021) is often referred to simply as 3D printing. Our machines and processes enable the use of metal powder for industrial additive manufacturing.

In additive manufacturing, process accuracy is crucial to achieve optimal flow properties of the powder. From the very beginning of the metal powder manufacturing process, weighing and feeding systems play a critical role in the quality of the additive manufacturing process, as it is a complex and in-depth manufacturing process that encompasses the entire printing workflow.

L.B. Bohle’s precision weighing and feeding systems for the production of metal powders enable optimal raw material management from the start of the production process and ensure a significant increase in product quality.

Your inquiry about our weighing systems

Metal Powder Blending in small and large quantities

Metal Powder Blending in Small and Large Quantities

The mixing of metal powders places high demands on the safety and quality of the 3D printing or additive manufacturing process.

When producing metal powders, the homogeneity of the mixture produced is critical. The aim of the mixing process is to achieve a uniform distribution of all components in the mixture.

Advantages of our Blenders for Metal Powder to the Additive Manufacturing

| Mixing elements integrated in the container lid ensure homogeneous, effective and, above all, machine-friendly mixing | |

| Double valve technology for dust-free operation | |

| Rotates up to 6 rpm | |

| Inertisation possible for preventing oxidation or explosive atmosphere |

| Less machine wear / less machine load | |

| No tumbling and therefore no heavy “weight load” on the blender | |

| No high-speed mixing impeller in the abrasive metal powder as in an active mixer, instead the powder slides gently through our mixing baffles. |

Labormischer – Mischen von Metallpulver in kleinen Mengen

LM 40 - Mixing of Metal Powder in Small Quantities

The LM 40 is the optimal mixer for mixing metal powder for use in the 3D printer or within additive manufacturing. The blender is driven by a three-phase motor, which is in the machine housing. The control system of the machine is also located there.

Scale-Up

The LM 40 provides a secured scale-up

Advantages in additive manufacturing:

- Results scalable to the desired production size

- Fast, uncomplicated and completely discharged

- Use of different containers and bins

- High flexibility and mobility

- LM 40 is mobile on wheels and can be used flexibly

Metallpulver sicher lagern: Container, Behälter und IBC

Safe Storage of Metal Powders: Containers, Bins and IBCs

Containers and bins are used in additive manufacturing for mixing, storing and transporting metal powders. All containers are specifically designed to meet the needs of the industry. An advantage of L.B. Bohle’s bins and containers is that they are easy and complete to clean.

In the additive manufacturing of metal powders, our containers can be used as

| Mixing containers | |

| Storage containers | |

| Transport containers. |

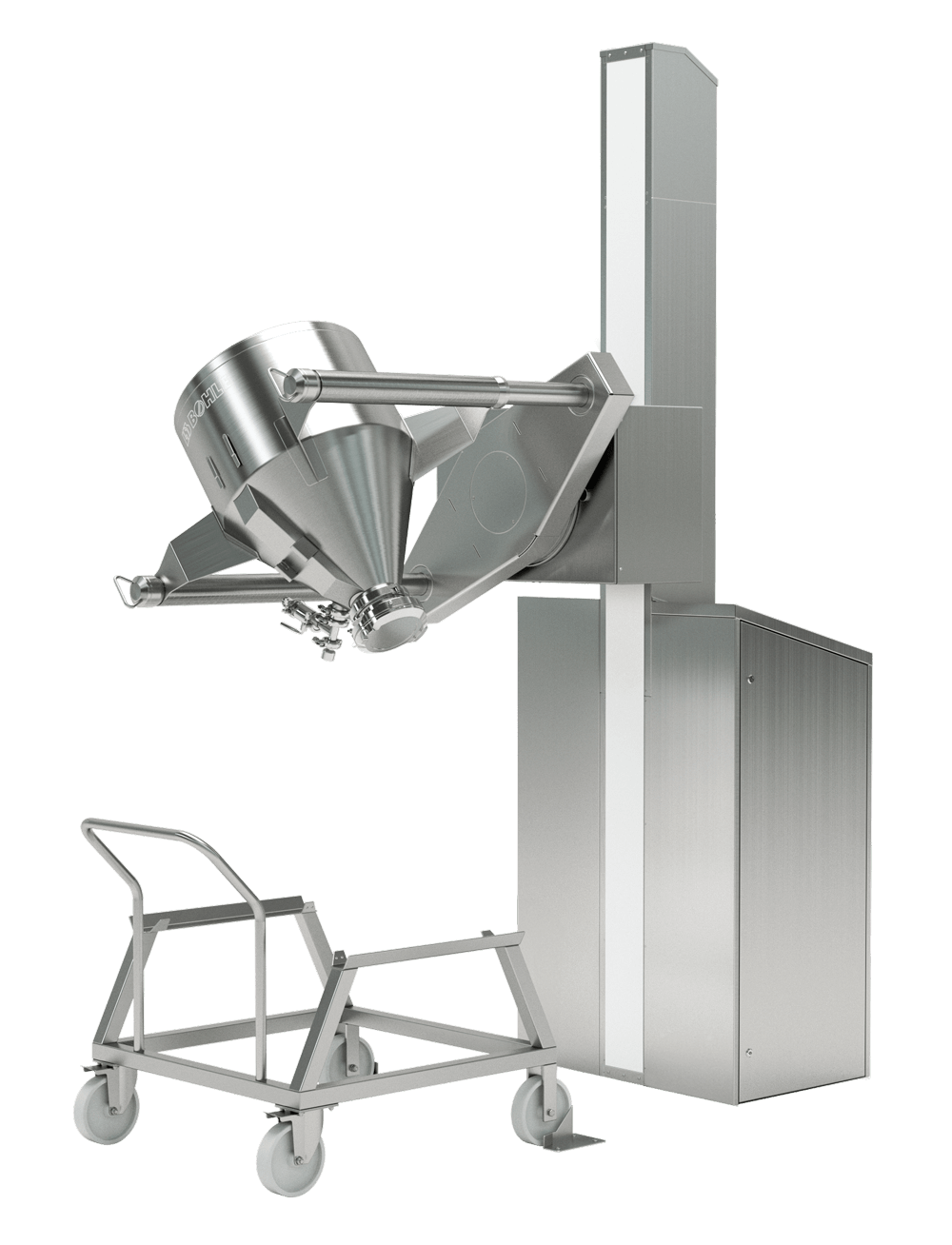

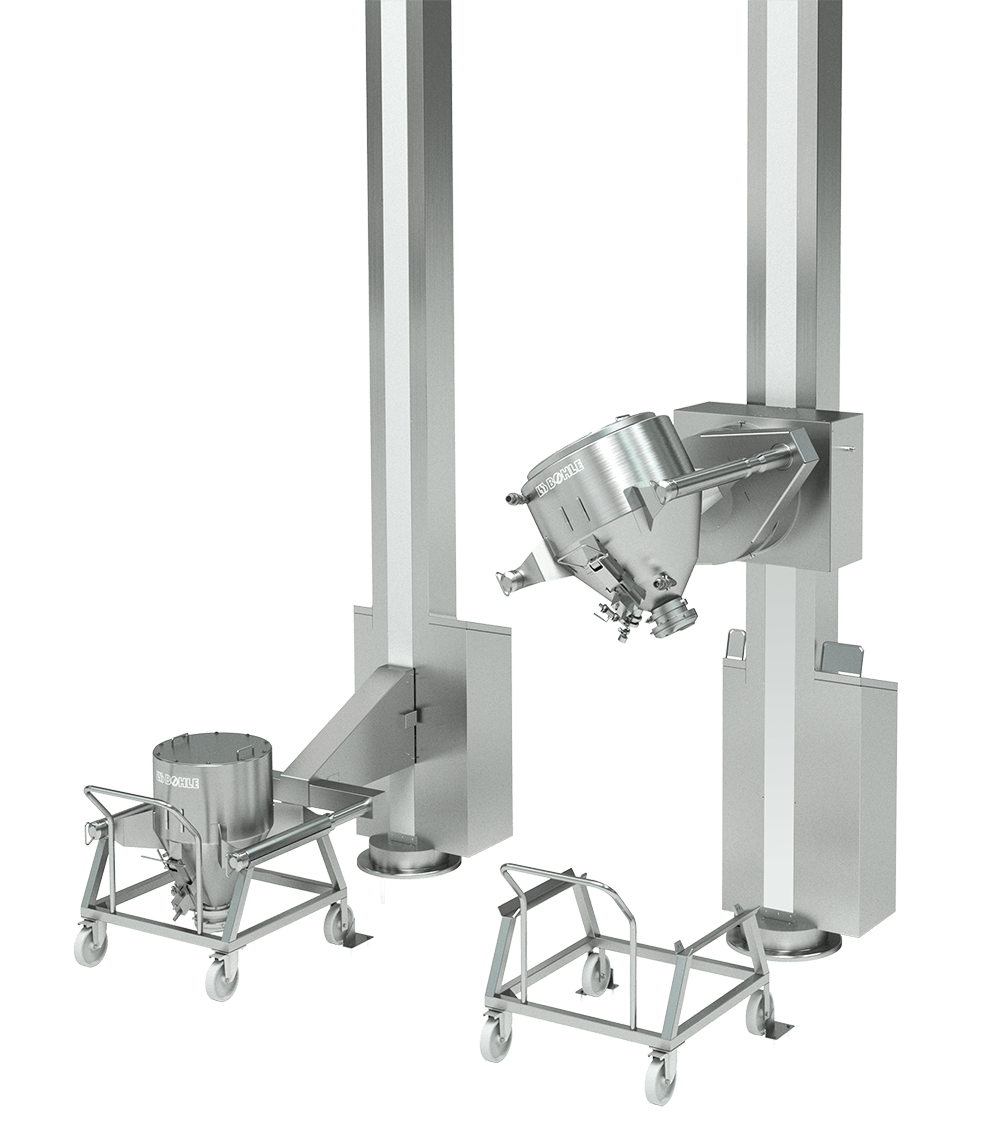

Lifting Columns HS – Safe Product Transport and Perfect Handling for the Production Process

Lifting Columns HS – Safe Product Transport and Perfect Handling for the Production Process

Our goal is to make your additive manufacturing process safer. With our stationary and space-saving lifting columns, we guarantee a safe manufacturing process of metal powders.

The liftung columns are flexible in use and their space-saving design allows them to be installed in the tightest of production areas.

For years, L.B. Bohle has successfully used an electrically driven chain drive. Competitors’ lifting columns are usually equipped with hydraulic lifting technology. The L.B. Bohle drive requires significantly less maintenance, is more hygienic and sustainable, as no oil is used.

Your inquiry about our lifting

Trenner Broschüre